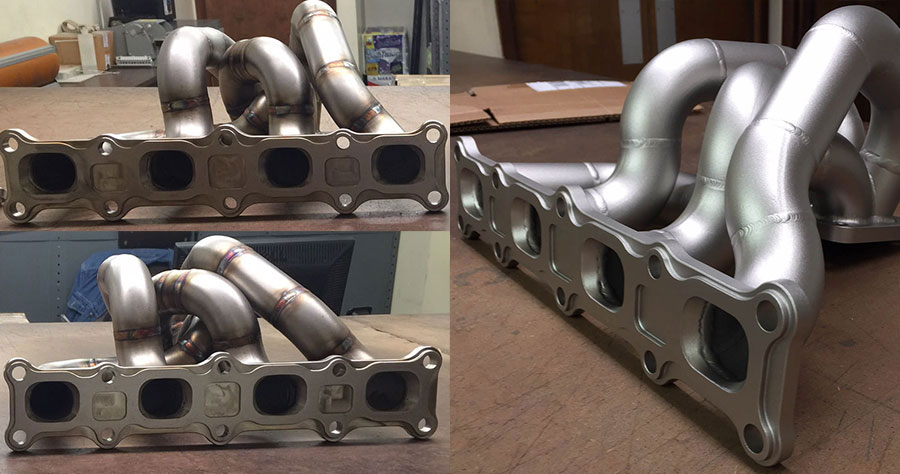

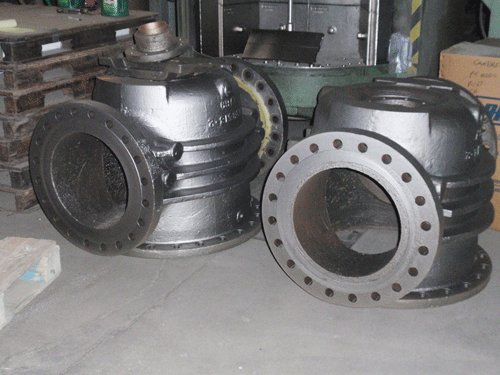

Abrasive Blasting is the operation of propelling any variety of abrasive grains at the surface of a substrate in a blast of pressurized air or by means of centrifugal force delivered by a wheel. This method of metal finishing will produce a variety of finishes depending on the air pressure, angle of the abrasive gun, distance from the workpiece, hardness of the surface, size and type of the abrasive used, or the speed and size of the wheel in a centrifugal wheel application. The blasting process may be used to blend surface imperfections, smooth or roughen a surface, create or shape a surface, remove and clean surface contaminants, or produce a textured final finish on certain pieces.

Finishing Systems’ job shop can produce the finish that you are trying to achieve. Our 24,000 sq. ft. job shop has an array of equipment to produce the finish you desire and to the specifications you require. We have proven time and again that no one in the industry offers as extensive a range of capabilities and equipment. Let us show you how our job shop can save you time and money by outsourcing your next application.

Send us a sample of your part and we will develop the most effective and efficient method to properly finish your part to your exact specifications. Regardless of the quantity (large or small batches); whether it requires abrasive blast finishing or vibratory finishing allow us to put our years of experience to work for you in your next project. Our unsurpassed service, expedient turnaround, and personal attention to your needs have made us a leader in this industry for over 40 years.

Finishing Systems has helped us in many jobs this year, pushing things through your shop for us. We are grateful for everything Finishing Systems has done for us; without your help we would not have been as successful.